Transform your garden from ordinary to extraordinary with the addition of a sturdy, handcrafted metal trellis! Climbing plants, whether vibrant flowers or lush vines, can dramatically enhance your outdoor space, but they need support to reach their full potential. A well-built trellis provides not only structural assistance for your climbing beauties but also adds a touch of elegant design to your garden's aesthetic. Imagine the satisfying sight of roses gracefully climbing a meticulously crafted metal structure, creating a breathtaking focal point. Forget flimsy, store-bought options that quickly rust and fail; this guide will empower you to build a lasting, beautiful trellis that will enhance your garden for years to come.

This step-by-step guide will walk you through the entire process, from gathering the necessary materials to the final touches of installation, ensuring you create a robust and visually appealing metal garden trellis. Let's get started and build that stunning garden feature!

Preparation and Safety Guidelines

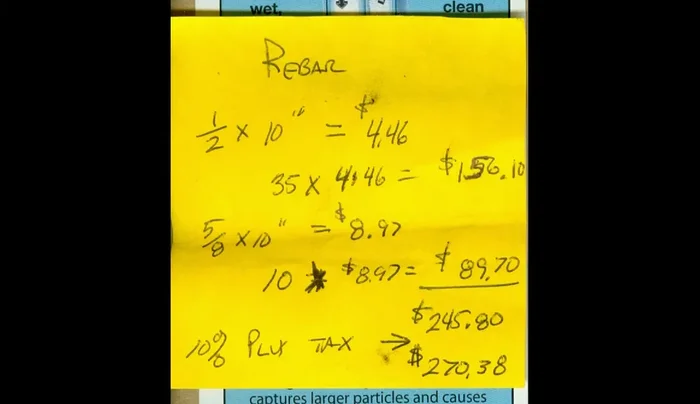

- Rebar (5/8 inch and 1/2 inch)

- Square tubing

- Plasma cutter

- Cut-off wheel

- 1/4 inch round stock

- Drill with roto hammer bit

- Welding machine (MIG welder with flux core wire recommended)

- Grinder with wire wheel

- Sledgehammer

- Tape measure

- Plywood

- Paint (e.g., Krylon 2x semi-gloss black)

- Support hooks (150 lbs rating)

- Concrete

- String

- Straight edge

- Always wear safety glasses and gloves when working with metal. Sharp edges and potential flying debris can cause serious injury.

- Use appropriate tools for cutting and shaping metal. Improper tools can lead to accidents and damage to the materials.

- Ensure the trellis is securely anchored to the ground to prevent it from tipping over, especially in windy conditions.

Step-by-Step Instructions

Prepare Support Brackets

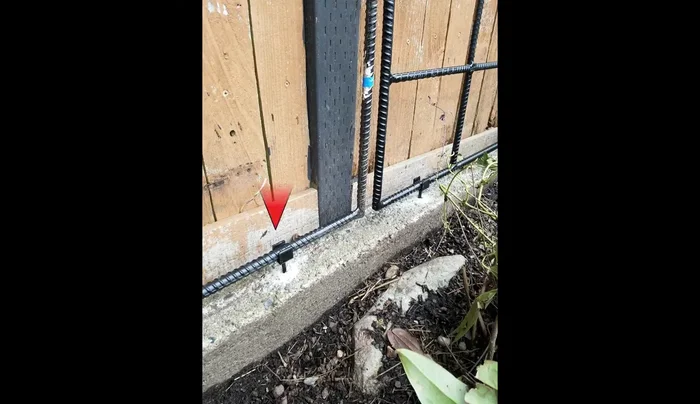

- Build support brackets to mount the trellis securely to the fence, embedding them in concrete for stability.

- Cut the square tubing to create U-shaped brackets that securely hold the 5/8 inch rebar.

- Cut the metal into 1-inch pieces using a cut-off wheel for a clean cut.

Prepare Support Brackets Create Trellis Frame

- Create the trellis frame using 5/8 inch rebar. Weld it directly to the fence.

Create Trellis Frame Build Trellis Sections Template

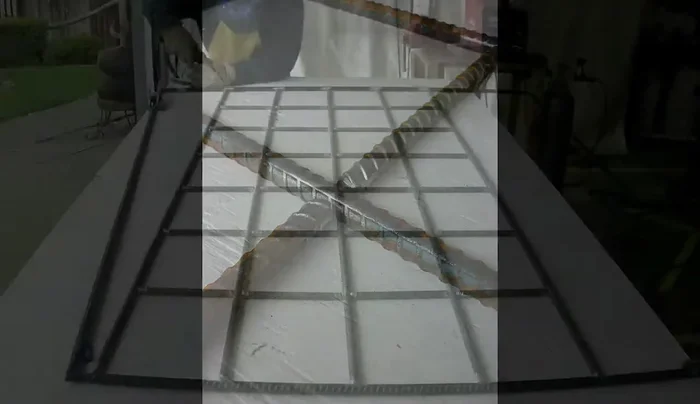

- Construct a template from plywood to ensure identical internal trellis sections.

Build Trellis Sections Template Prepare Rebar for Internal Structure

- Cut and prepare the rebar for the trellis internal structure. Clean rust and paint from the rebar where welding will take place.

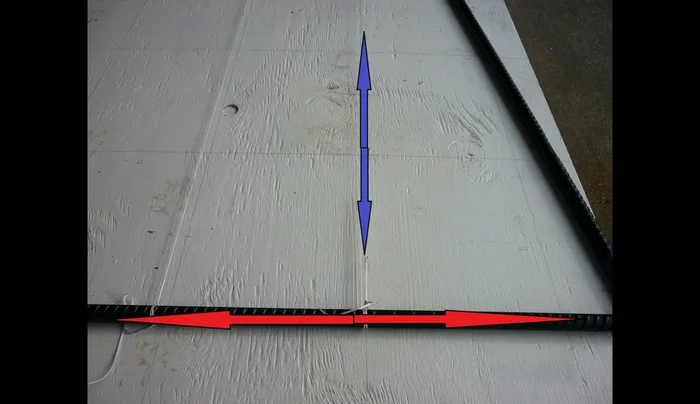

- Prepare the trellis frame sections outside to properly lay them on the template for consistent spacing.

- Use string to mark horizontal lines on the trellis frame, ensuring accurate placement on the template.

Prepare Rebar for Internal Structure Assemble Trellis Sections

- Place the rebar on the template, aligning it with marked lines. Adjust for uneven fence post spacing if necessary.

- Weld the internal rebar structure of the trellis sections according to the template.

Assemble Trellis Sections Connect Trellis Sections to Frame

- Customize and weld the rebar pieces that connect the trellis sections to the frame, accounting for non-square frame shapes.

Connect Trellis Sections to Frame Finish and Install

- Grind down welds for a smooth finish.

- Paint the entire trellis structure with a protective coat.

- Install the completed trellis sections into the support brackets.

Finish and Install

Read more: Miniature Spider Welding Tutorial: Crafting a Tiny Metal Arachnid

Tips

- Use flux core wire for welding if there is wind.

- Use a hot day to dry rebar after cleaning to prevent re-rusting.

- Build the trellis in sections for easier maintenance and handling.

- Use support hooks with a higher weight rating (150lbs) until the support brackets are installed.

- Clean at least an inch of paint and rust around weld points.