One-piece metal box fabrication offers a sleek, robust, and cost-effective solution for a variety of applications, from electronics enclosures to custom storage solutions. The seamless construction eliminates the need for welding or assembly, resulting in a stronger, more aesthetically pleasing end product. This technique, while seemingly complex, can be mastered with the right tools, techniques, and a clear understanding of the process. Precision is key, and careful planning will prevent costly mistakes and ensure a successful outcome.

This guide provides a comprehensive, step-by-step approach to fabricating your own one-piece metal box, detailing each stage from initial design and material selection to the final finishing touches. Let's delve into the process, learning how to transform a flat sheet of metal into a functional and attractive three-dimensional enclosure.

Preparation and Safety Guidelines

- Scriber

- Metal Shears

- Magna Bend

- Spot Welder

- Always wear appropriate safety glasses and hearing protection when operating metalworking machinery. Flying debris and loud noises are common hazards.

- Use caution when handling sharp metal edges and points. Wear gloves and use appropriate tools to avoid cuts and injuries.

- Ensure proper ventilation when welding or using processes that produce fumes or gases. Inhaling these substances can be harmful to your health.

Step-by-Step Instructions

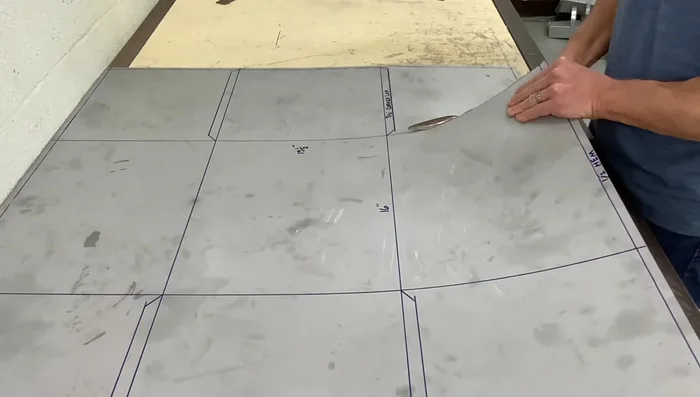

Marking and Cutting

- Mark the 1/2 inch hem on all four sides of the metal sheet.

- Cut the metal sheet according to the scribed pattern.

Marking and Cutting Bending Hems

- Bend all four hems (safety edges) over 180 degrees.

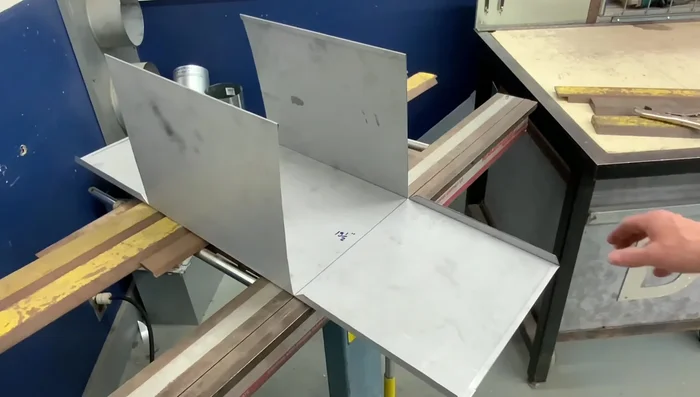

Bending Hems Bending Sides and Lap Seams

- Bend the two longer sides (with corner lap seams) up 90 degrees. Ensure the corner lap seam bends up at the same time as the side.

Bending Sides and Lap Seams Preparing for Corner Joining

- Slightly open the hems to receive the corner lap seam.

Preparing for Corner Joining Forming the Box

- Carefully bend the corner lap seams to the inside of the box.

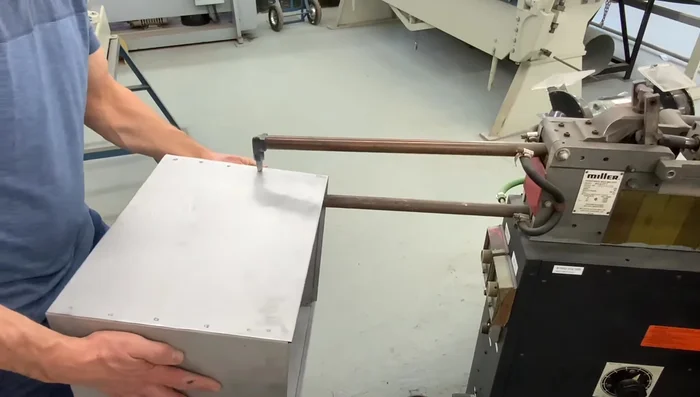

Forming the Box Securing the Corners

- Use a spot welder to fasten the corners. Alternatively, pop rivets, screws, or welding (for heavier gauge metal) can be used.

Securing the Corners

Read more: Miniature Spider Welding Tutorial: Crafting a Tiny Metal Arachnid

Tips

- Ensure the corner lap seam remains on the inside of the box during bending.

- Push the sides out to allow the side to come up and into the hem during corner joining.