In today's compact living spaces, maximizing functionality without sacrificing style is a constant challenge. A cluttered workspace can quickly derail productivity, and traditional desks often consume valuable floor space. This project offers a solution: a sleek, space-saving wall-mounted desk designed to seamlessly integrate into any room. Featuring a cleverly concealed compartment for storing essential items and a slimline drawer for easy access to frequently used tools or supplies, this desk provides ample workspace while maintaining a clean, uncluttered aesthetic. Forget bulky furniture – this design prioritizes both practicality and a minimalist approach to organization.

This detailed guide will walk you through each step of building your own custom wall-mounted desk, complete with a hidden compartment and a sleek, space-saving drawer. From selecting the right materials to assembling the components and securing it safely to your wall, we'll provide clear instructions and helpful tips to ensure a successful and aesthetically pleasing outcome. Let's begin!

Preparation and Safety Guidelines

- Table saw (or alternative cutting tools)

- Miter saw (optional)

- Circular saw (optional)

- Miter box (optional)

- Drill

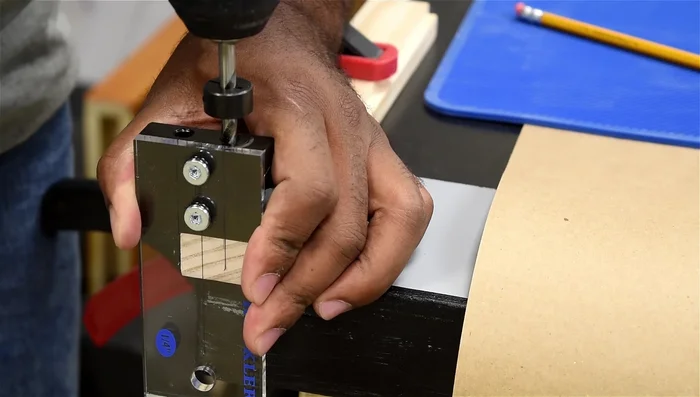

- Dowel jig

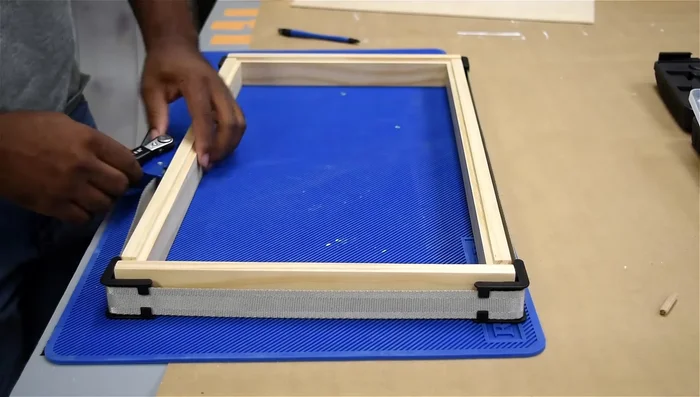

- Band clamp

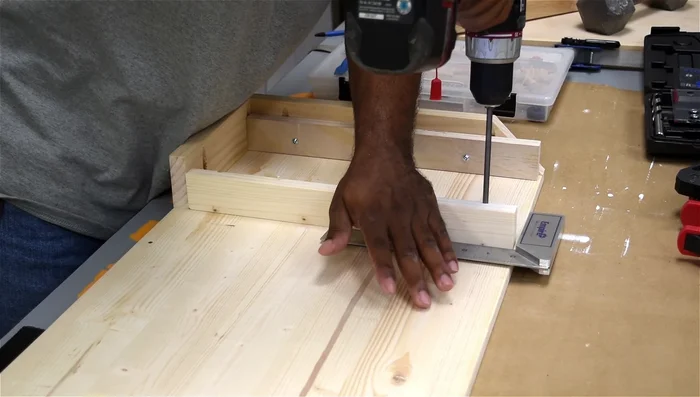

- Pocket hole jig

- Router

- Sandpaper

- Wood glue

- Wood filler

- Nails

- Screws

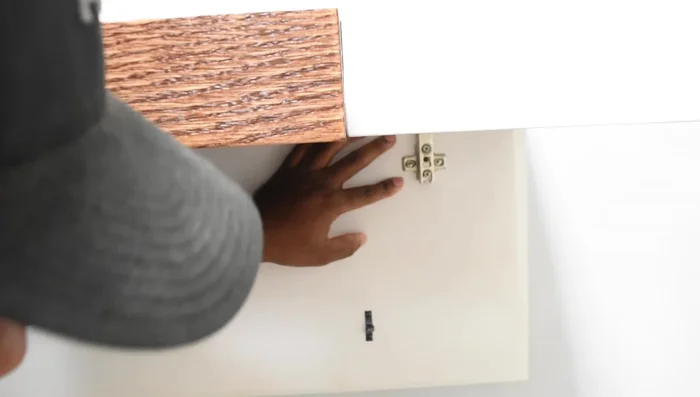

- Hinges

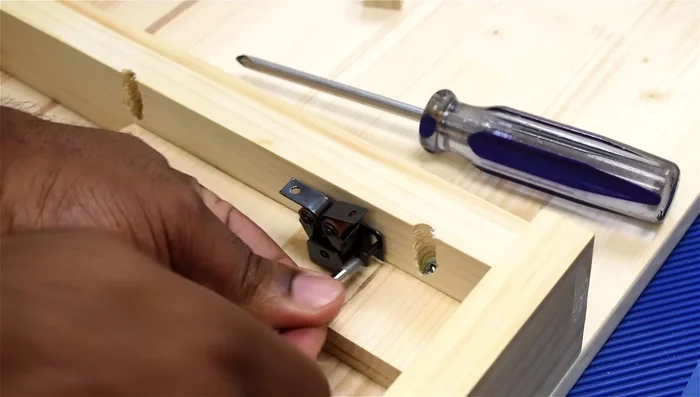

- Roller catch

- LED strip lights

- Cable stapler or staple gun

- Measuring tools

- Level

- Paint

- Wood stain

- Furniture wax

- Chain

- Ensure the wall you choose can support the weight of the desk and its contents. Use appropriate wall anchors and follow manufacturer's instructions for load-bearing capacity.

- Precise measurements are crucial for a successful build. Double-check all measurements before cutting any materials or drilling any holes.

- Always disconnect power to any electrical outlets near the installation area before drilling or working with power tools to prevent electrical shock.

Step-by-Step Instructions

Cutting and Preparation

- Cut the desk top and other pieces according to your design. Label each piece for easy tracking.

- Sand all pieces thoroughly to prepare for assembly.

Cutting and Preparation Drawer Construction

- Create a simple box with a plywood bottom, using a rabbet joint (or simply attaching the plywood) for a flush fit.

- Assemble the drawer box using dowel joints and glue. One dowel per corner is sufficient with adequate glue.

- Clamp the drawer box to ensure squareness, apply glue to joints, and let it dry completely.

- Create drawer slide tracks using a router and making sure there's a little play for smooth operation.

Drawer Construction Desk Frame Assembly

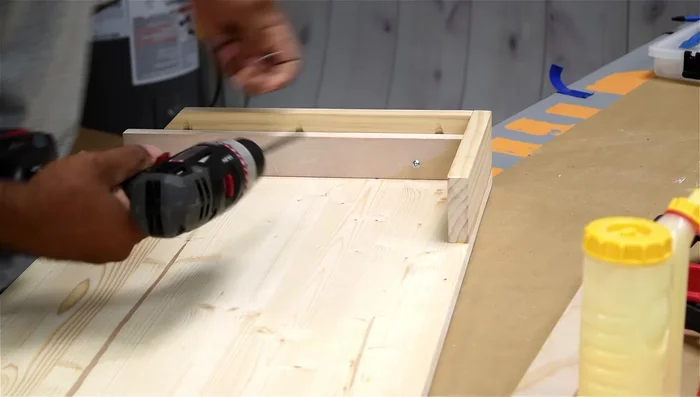

- Assemble the desk frame using pocket holes and glue for added strength.

- Attach the inner support pieces for the swing-down door.

- Attach the back support panel using pocket holes and glue, creating mitered corners.

- Install the lower panel and bottom using pocket holes and glue.

Desk Frame Assembly Hardware Installation

- Install the drawer slides, ensuring accurate spacing and alignment.

- Install hinges for the hidden compartment door in a reversed manner for this specific design.

- Install the roller catch and its counterpart on the door and frame for closure.

- Mark and install wall brackets, ensuring level alignment.

Hardware Installation - Cut out sections in the desk top and back panel to accommodate the brackets.

- Attach the desk to the wall brackets using screws.

Hardware Installation Finishing Touches

- Install the LED strip lights, creating a recess for a flush fit.

- Secure LED wiring and controller.

- Fill imperfections with wood filler and sand smooth.

- Paint the desk and stain the drawer (optional).

Finishing Touches - Attach the final hardware and accessories.

Finishing Touches

Read more: Ultimate Guide to Harmonious Bedroom Furniture Arrangement

Tips

- Use a variety of cutting tools based on your preference and material.

- For drawer construction, the rabbet joint is superior to simple attachment for a more professional finish, but the simpler method is a viable alternative.

- Use a dowel jig and clamps for accurate dowel joint construction.

- Pre-drill holes for screws to prevent splitting.

- Check for squareness frequently during assembly.