A malfunctioning evaporator fan motor in your refrigerator can lead to a frustrating array of problems: inconsistent cooling, excessive frost buildup, and ultimately, spoiled food. This seemingly small component plays a crucial role in maintaining the proper temperature within your appliance, and its failure can quickly escalate into a major inconvenience. Ignoring the issue will only lead to further complications and potentially more costly repairs down the line. Fortunately, replacing the evaporator fan motor is often a manageable DIY project, saving you the expense of a professional service call.

This simple guide will walk you through the process of diagnosing a faulty evaporator fan motor and replacing it with a new one. For a step-by-step walkthrough that'll have your refrigerator humming along again in no time, read on to learn how to tackle this common refrigerator repair.

Preparation and Safety Guidelines

- Quarter-inch nut driver

- Needlenose pliers

- Always disconnect the refrigerator from the power source before starting any repairs. Failure to do so could result in electric shock.

- Wear appropriate safety glasses to protect your eyes from debris or flying parts.

- If you are uncomfortable performing this repair, or unsure about any step, contact a qualified appliance repair technician.

Step-by-Step Instructions

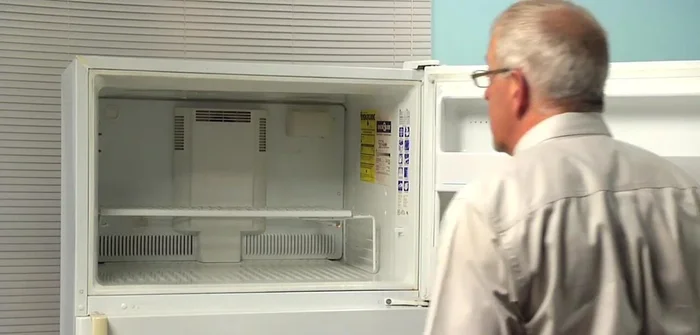

Power Disconnection and Freezer Preparation

- Disconnect power to the refrigerator by unplugging it.

- Open the freezer door completely and remove all items and shelves.

- Remove the ice maker (if applicable).

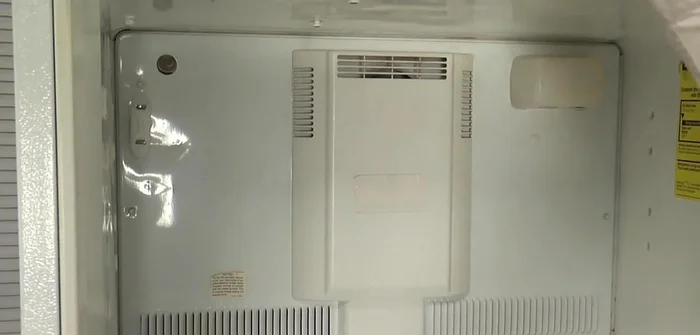

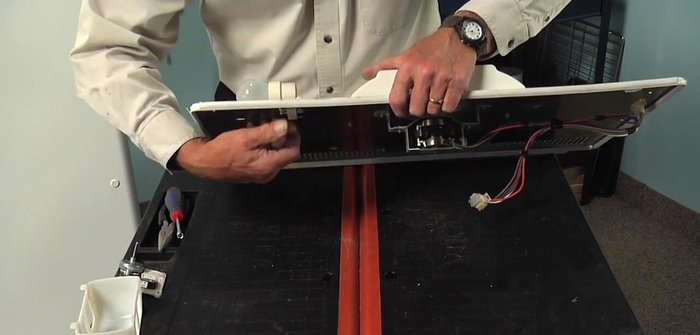

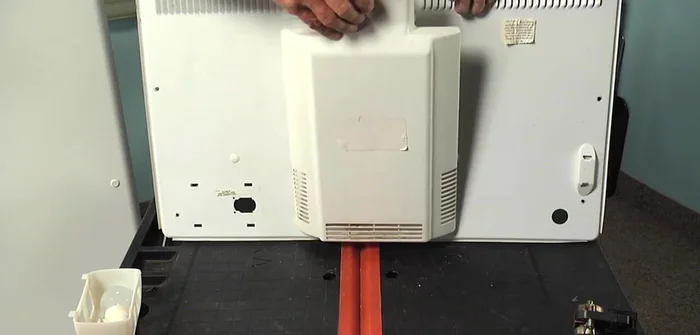

Power Disconnection and Freezer Preparation Evaporator Panel Removal

- Remove the cap from the ice maker fill tube and remove four quarter-inch hex head screws securing the evaporator panel.

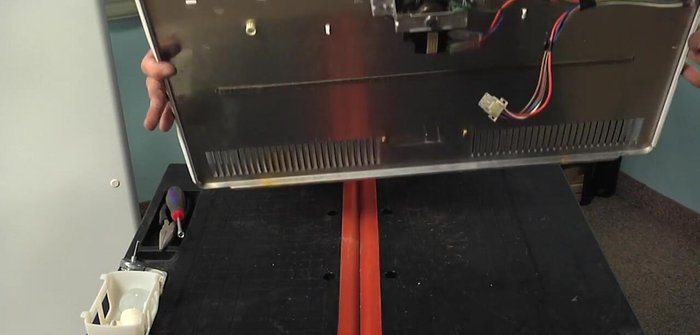

- Tilt the evaporator cover forward and lift it out.

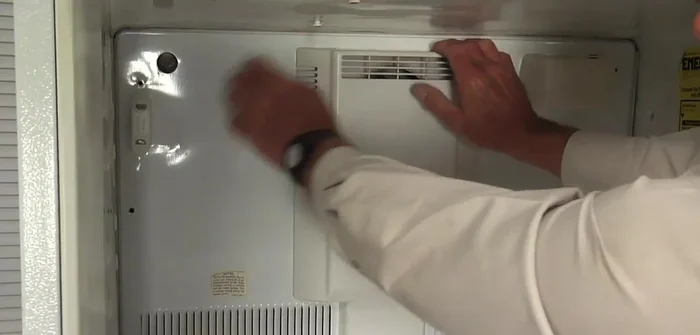

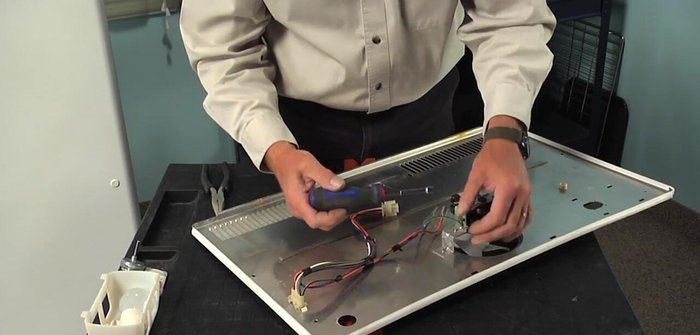

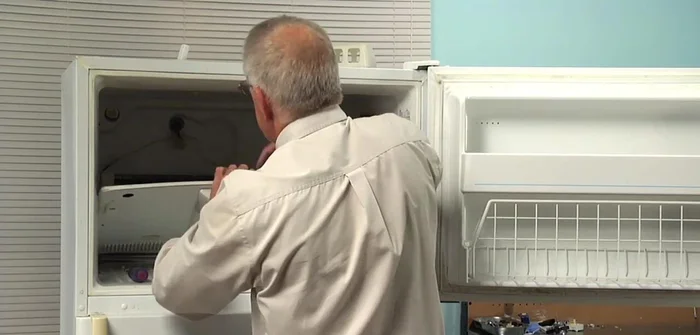

- Disconnect the wires to the light bulb and the evaporator fan motor harness.

Evaporator Panel Removal Light Bulb and Socket Removal

- Remove the light bulb shield by depressing the top and releasing the locking tabs.

- Remove the light bulb and socket by depressing the top tab and tilting it out.

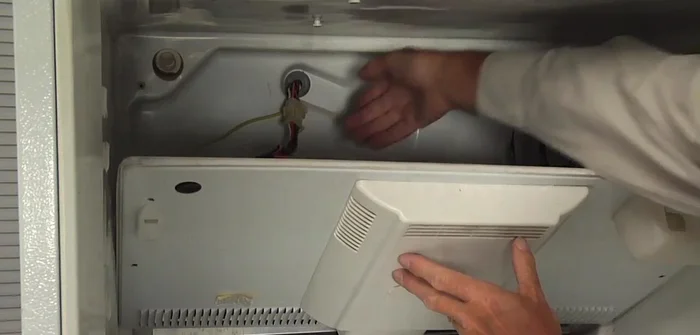

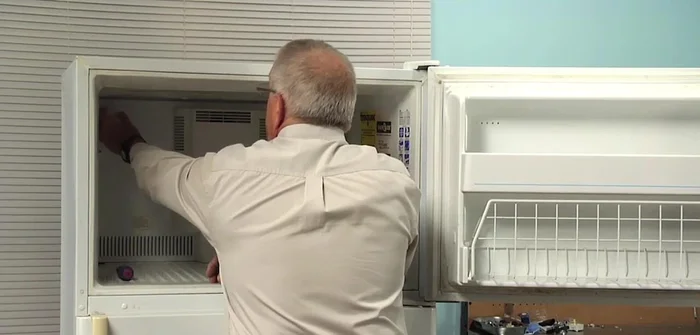

Light Bulb and Socket Removal Evaporator Fan Motor Removal

- Remove the evaporator fan cover by releasing the six plastic clips.

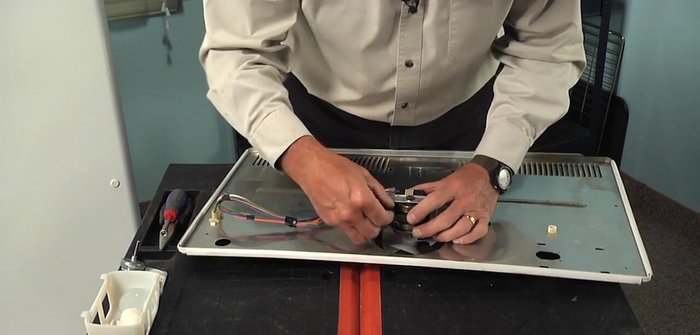

- Remove the ground wire from the motor (use needlenose pliers if needed).

- Remove the two motor wires by depressing the locking tabs.

- Remove the ground screw from the motor bracket.

Evaporator Fan Motor Removal - Remove the two screws securing the motor bracket and lift off the bracket.

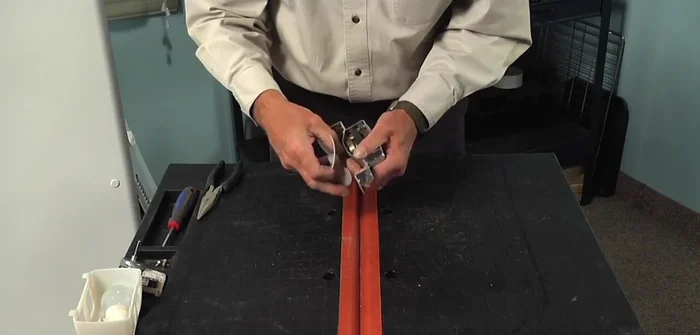

- Remove the fan blade from the old motor.

- Remove the old motor, noting the rubber bushings.

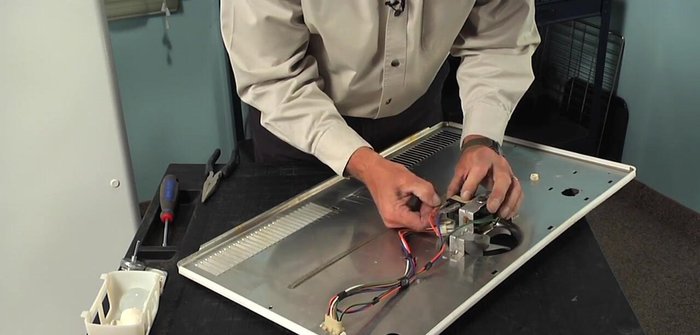

Evaporator Fan Motor Removal New Motor Installation

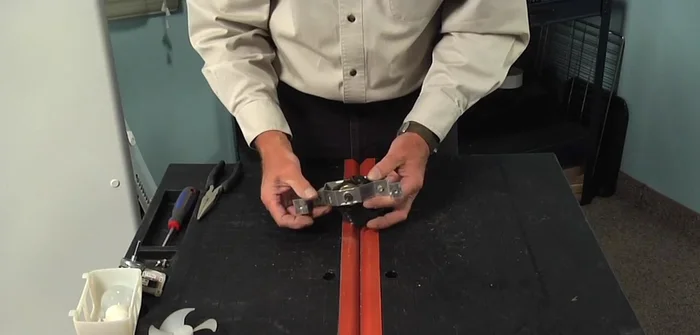

- Install the new motor, ensuring the bushings are correctly positioned.

- Reinstall the motor bracket and screws.

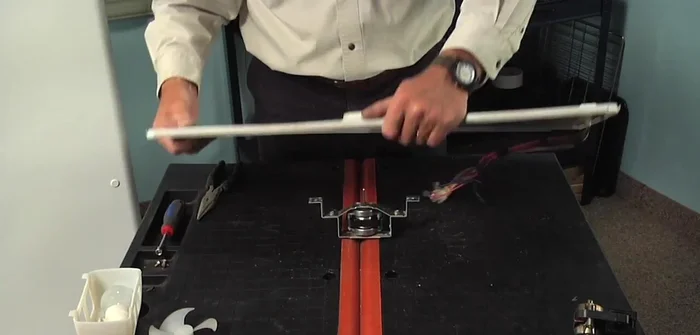

- Reattach the fan blade.

New Motor Installation Reassembly

- Reinstall the evaporator fan cover.

- Reconnect the motor harness and light bulb wires.

- Reinstall the evaporator cover and screws.

Reassembly Final Steps and Power Restoration

- Reinstall the ice maker (if applicable), shelves, and reconnect the power.

Final Steps and Power Restoration

Read more: Fix Washing Machine Won't Spin: Quick & Easy Motor Coupler Replacement

Tips

- It's easier to remove the light bulb and socket before reinstalling the evaporator cover to avoid struggling with wires.

- Ensure the rubber bushings are correctly positioned on the motor during installation.

- Tighten all screws securely.

- Check the perimeter gasket is firmly in place before reinstalling the cover.