Tired of flimsy, unattractive towel holders that constantly fall apart? Ready to elevate your bathroom's aesthetic with a piece of handcrafted elegance? Then prepare to be amazed by the beauty and durability of a towel holder built using precision case miter joints. This woodworking tutorial will guide you through creating a stunning, functional addition to your home, a testament to your craftsmanship and a source of daily pride. We’ll explore the intricacies of this joinery technique, revealing the secrets to achieving perfectly aligned corners and a finish that will impress even the most discerning eye.

This project is ideal for woodworkers of intermediate skill levels, offering a satisfying challenge and a rewarding outcome. From selecting the perfect wood to the final sanding and finishing touches, we'll cover every step in detail. Let's dive into the step-by-step instructions and build your magnificent towel holder together!

Preparation and Safety Guidelines

- Fusion 360 (for modeling)

- Table Saw

- Miter Saw

- Sandpaper (120 grit, 220 grit)

- CA Glue

- Wood Glue

- Forstner bit

- Clamps

- Painter's Tape

- Mr. Cornwall's Super Duper Everlasting Oil

- Always wear safety glasses when using power tools. Wood dust and flying debris can cause serious eye injuries.

- Use clamps to secure your workpiece throughout the entire process, especially when using hand tools or during gluing. This prevents shifting and ensures accurate joints.

- Ensure your blades are sharp. Dull blades require more force, increasing the risk of kickback and inaccurate cuts. Regularly inspect and sharpen or replace blades as needed.

Step-by-Step Instructions

Design and Planning

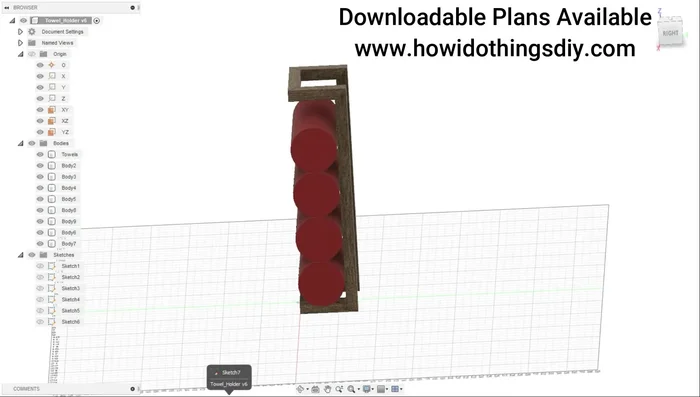

- Design and Modeling in Fusion 360

- Create Cut List from Model

Design and Planning Prepare the Wood

- Rip Walnut to Strips

- Cut to Rough Length (add 1/4 inch)

- Fill Knots and Holes with CA Glue

- Sand CA Glue and Square Profiles on Table Saw

Prepare the Wood Cut Miter Joints

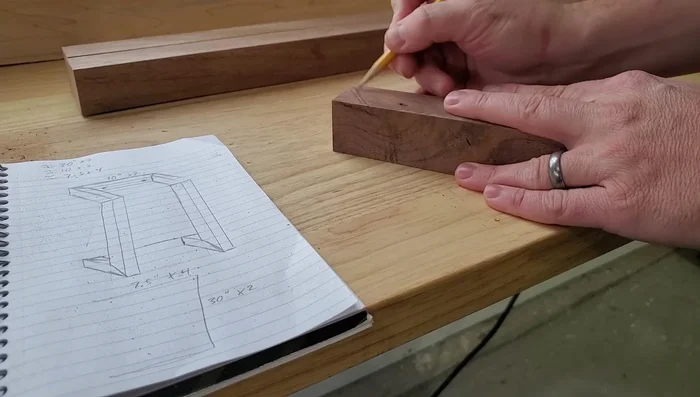

- Rough Mark Miter Joints

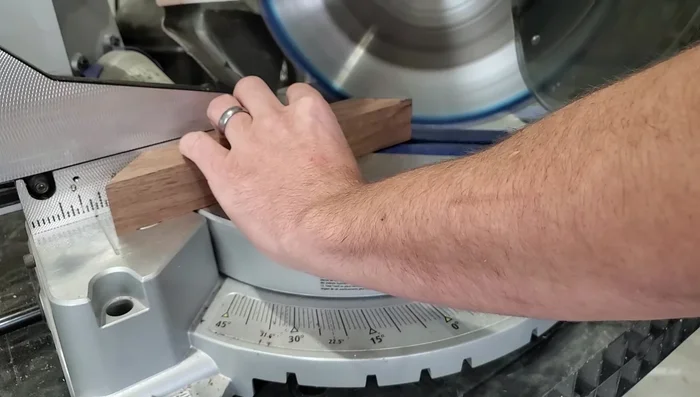

- Cut Miter Joints

Cut Miter Joints Create and Install Case Miter Joints

- Create and Install Case Miter Joints (Maple Spline)

- Cut spline pieces

- Cut slots for splines

- Glue and Clamp

Create and Install Case Miter Joints - Flush Cut Spline

Create and Install Case Miter Joints Sanding

- Sanding (before and after final assembly)

Sanding Prepare for Installation

- Drill Countersunk Holes

Prepare for Installation Finishing

- Apply Finish (Mr. Cornwall's oil)

Finishing

Read more: DIY Mason Jar Soap Dispensers: A Step-by-Step Guide with Two Stunning Designs

Tips

- Model miter joints to determine direction

- Add 1/4 inch to each piece for rough cut

- Use accelerator with CA glue for quick drying

- Reality check miter cuts

- Dry fit splines before gluing