Cracked concrete is an unsightly and potentially structural problem that plagues homeowners and property owners alike. Whether it's a driveway riddled with spiderweb cracks, a crumbling patio, or a foundation showing signs of stress, the cost of professional repair can be prohibitive. Fortunately, tackling minor concrete cracks yourself is achievable with the right tools and a little know-how. This DIY approach not only saves you money but also empowers you to maintain your property's integrity. Using readily available materials and a product like Crack Weld Pro, you can effectively restore the appearance and structural soundness of your concrete surfaces.

This guide provides a comprehensive, step-by-step approach to repairing your concrete cracks using Crack Weld Pro, a high-performance solution designed for ease of use and lasting results. From preparing the crack to the final finishing touches, we'll walk you through every stage of the process, ensuring a professional-looking and durable repair that will stand the test of time. Let's get started!

Preparation and Safety Guidelines

- Crack Weld Pro concrete crack repair kit

- Dual cartridge caulking gun

- Putty knife

- Silica sand

- Gloves

- Nozzles

- Small cups

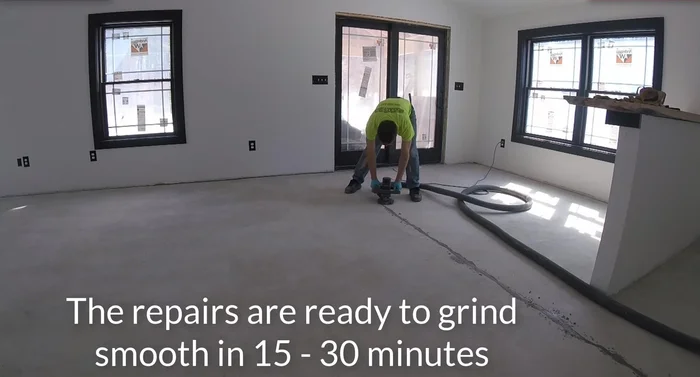

- 5-inch grinder with vacuum attachment

- Diamond cup wheel

- Always wear appropriate safety gear, including safety glasses, gloves, and a dust mask, to protect yourself from dust, debris, and chemical splashes.

- Ensure adequate ventilation in the work area to avoid inhaling harmful fumes, especially when using Crack Weld Pro or other chemical products.

- Before starting any repair, carefully assess the crack to determine its cause and extent. If the crack is large, structurally significant, or indicates a more serious foundation problem, consult a professional contractor.

Step-by-Step Instructions

Prepare Crack Weld Pro

- Remove the stopper and attach the backflow resistor.

- Attach the nozzle and load the cartridges into the caulking gun.

- Purge a small amount of material to ensure thorough mixing.

Prepare Crack Weld Pro Prepare the Crack

- Clean the crack area.

- Wet the crack with water.

- Add silica sand to the wet crack.

Prepare the Crack Apply Crack Weld Pro

- Mix the sand with the repair material to form a paste using a putty knife.

- Force the paste into the crack, leaving it slightly higher than the surrounding concrete.

- Repeat steps 5-8 for the entire crack, working in 5-10 foot sections.

Apply Crack Weld Pro Cure and Finish

- Allow the repair material to harden.

- Grind off the excess repair material using a grinder with a vacuum attachment.

Cure and Finish

Read more: Fixing Drywall Nail Pops: A Quick and Easy DIY Guide

Tips

- Work steadily to avoid the material drying before you can finish.

- Leave the repair material slightly high initially, as you will grind it down later.

- Use a vacuum attachment with your grinder to minimize dust.